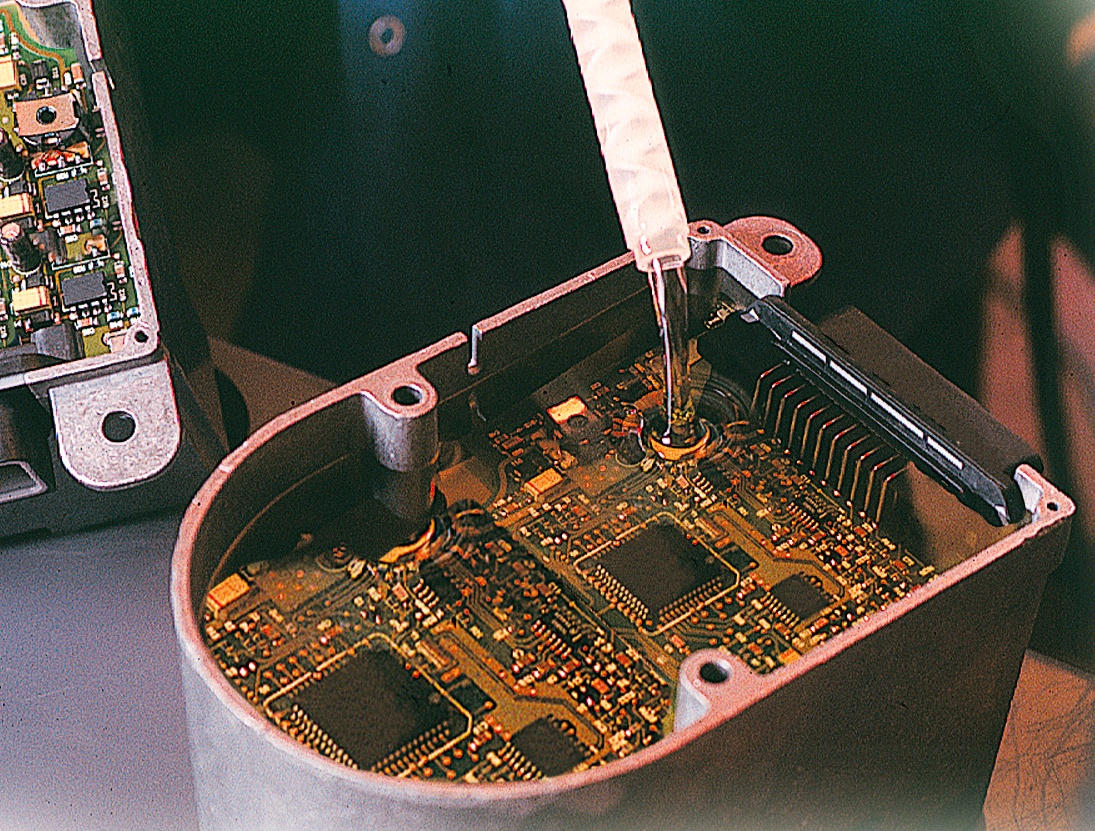

Potting![]()

Potting and encapsulating compounds are used to provide mechanical reinforcement to housed assemblies,

to fill large voids, and to protect components from the effects of exposure to chemicals, moisture, mechanical

shock, and vibration. Sealing components with potting and encapsulating compounds prevents corrosion and

ensures long-term integrity of the device.

Variables to consider when selecting a potting or

encapsulating material include:

• Viscosity of uncured compound

• Dispensing requirements

• Device operating temperature

• Desired chemical resistance

• Desired thermal conductivity

• Desired flame retardants

• Hardness of cured product

• Overall cost

There are a variety of potting and encapsulating

compounds to choose from – epoxy, hot melt, silicone,

and urethane. The thermal properties of epoxy

and silicone systems make them ideally suited for

applications exposed to temperatures above 257°F

(125°C). If a soft, flexible material is needed,

particularly at low temperatures, then a urethane,

silicone or hot melt material may be used.*

*text form Loctite Corp. 2008 Source Book.

Wilcox-Slidders, Inc. 18 Passaic Ave. Fairfield NJ 07004 • 973-575-8600 • Fax: 973-575-7329

Contact E-Mail: Sales@wilcox-slidders.com

Home • 3m • Loctite • Devcon • Helicoil • Starrett • Line Card • Cutting Tools • Abrasives • Adhesives • On Line Store • Contact Us • About Us